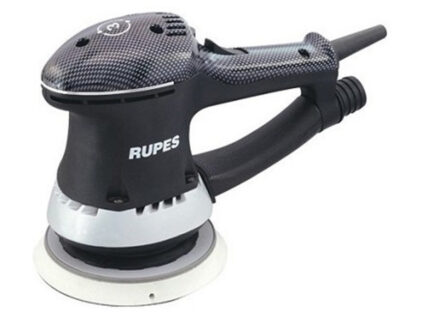

- Advanced brushless motor.

- 150mm Velcro pad.

- 3mm Orbit.

- 250W

- 1.2Kg.

- Suitable for final finishing.

The new SKORPIO E represents the first RUPES random orbital electric sander using advanced BRUSHLESS motor technology. The high efficiency brushless motor guarantees power and performance for virtually any application, maintaining the speed even under heavy load conditions.

The Skorpio E features optimized ergonomics which make it comfortable and easy to use, while the innovative design provides incredible maneuverability and balance to guarantee precise and efficient sanding results. SKORPIO E is also quiet, extremely lightweight, and with a low vibration level maximizing operator comfort.

3mm Orbit for Final Finishing Applications:

The 3mm orbit is designed for finishing applications that use grade P320 and higher abrasives. The small orbit, combined with the high rpm and quality abrasives, delivers a high quality finish that is perfectly prepared for paints and other coatings. Other orbit versions available. |

The Skorpio E features:

| New Brushless Electric Motor The innovative design of the brushless motor is incredibly reliable and durable. Well engineered to perform at the highest levels and featuring fewer components than traditional electric sanders the Skorpio E motor guarantees low maintenance. A specially designed housing seals the motor and prevents damage by preventing dust from entering the motor. |

| Ergonomic Design Through extensive ergonomic research the Skorpio E has been designed to provide the best user experience and maneuverability. A rubberized grip and comfortable hand position provide comfort and stability during operation |

Throttle Lever Variable speed lever provides precision control of tool operation.

|

Central Vacuum Models Wyatt Machine Tools sell models RX253A and RX256A configured for external dust extraction systems. |

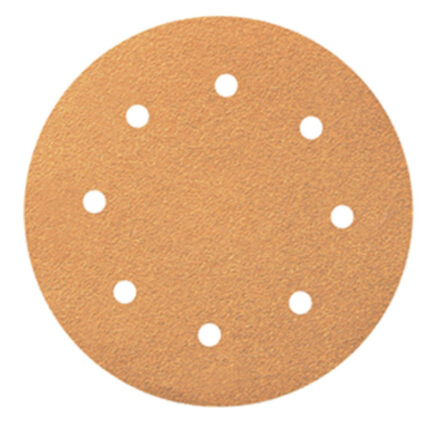

Multi-hole Backing Pads

The multihole pattern combined to the 10 channels obtained on the side of the backing pad provides an impressive air flow that increases the dust extraction during the sanding on both horizontal and vertical surfaces. This guarantees a better cleaning of the working area and therefore a better working conditions. Two of the side channels are connected directly to the central hole with the function to dissipate the heat during the backing pad rotation. This new model of backing pad has been designed to obtain a low center of gravity which ensures a better control and precision during all phases of the sanding process.

Multihole slim backing pad

Code: 981.600

Diameter: 150mm (6”), 5/16″ fitting

Recommended Pads:

| 150 | Velcro | Multi Hole Slim | Hard | 5/16″ | 981.600 |

Reviews

There are no reviews yet.